The HS188 Hall Effect Sensor is a temperature stabilized stress sensor. Superior high temperature performance is achieved through dynamic offset cancellation utilizing chopper stabilization techniques. This approach reduces the offset voltage typically caused by device overmolding, temperature dependency, and thermal stress.

The HS188 contains the following on a single chip: voltage regulator, Hall voltage generator, small signal amplifier, chopper stabilizer, Schmitt trigger, Advanced DMOS wafer fabrication processes are used to take advantage of low voltage requirements, component matching, very low input offset errors, and small component geometries.

The device requires both south and north pole magnetic fields to operate. In the presence of a south pole magnetic field of sufficient strength, the device output sensor turns on and only turns off in the presence of a north pole magnetic field of sufficient strength.

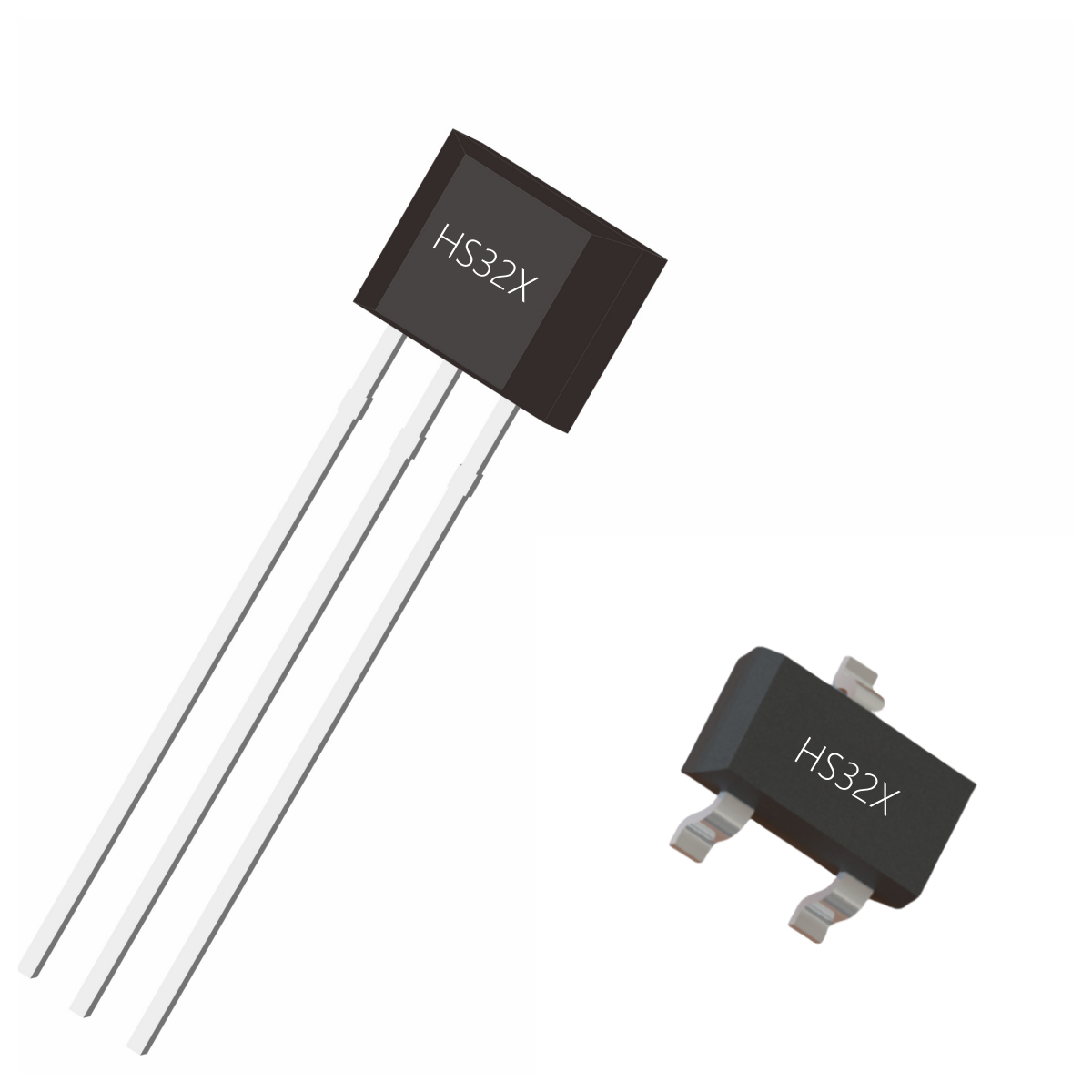

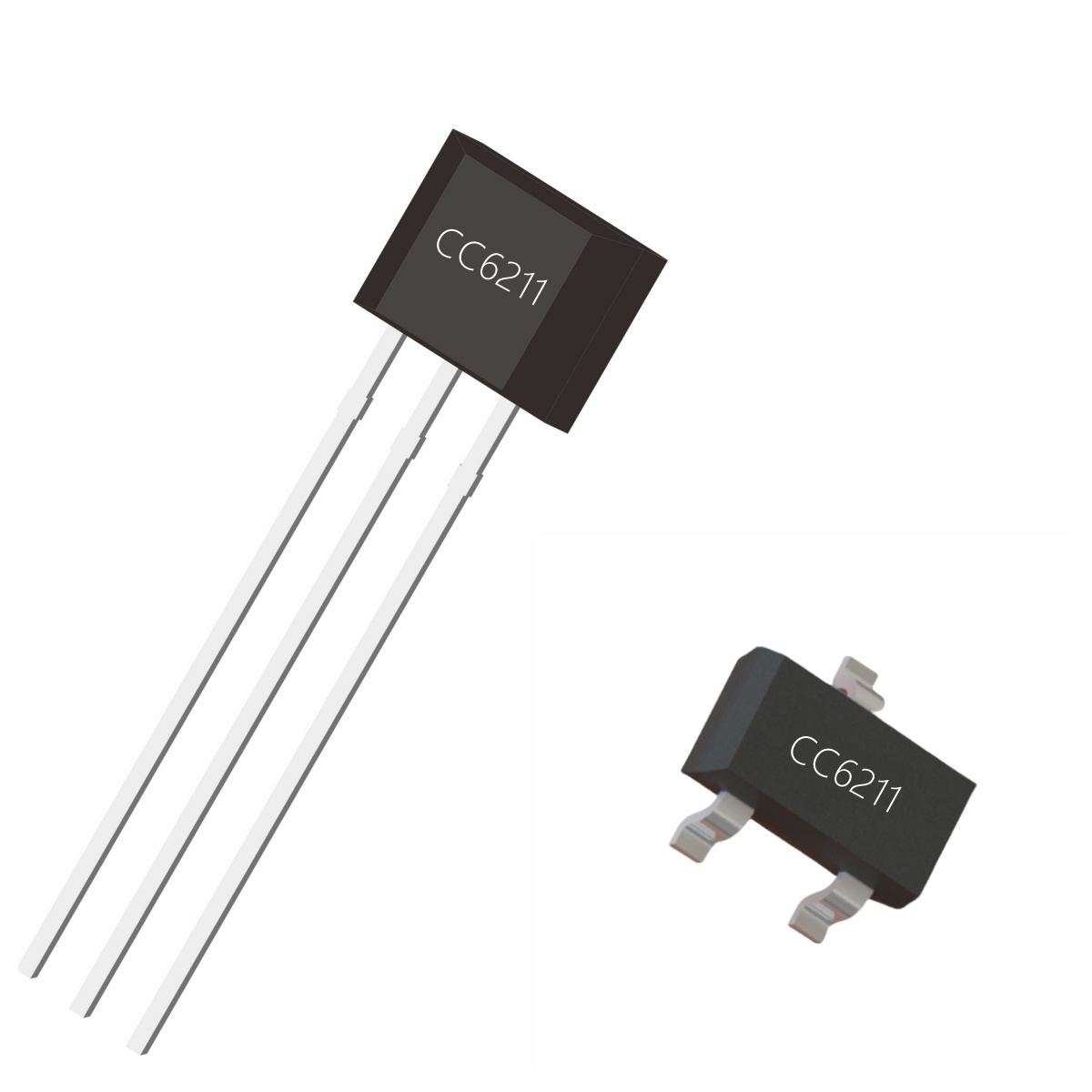

The HS188 is rated for operation from -40°C to 85°C for the E temperature range and -40°C to 125°C for the K temperature range. Two package types provide magnetically optimized solutions for most applications. The SO package is a SOT-23, a miniature low profile surface mount package, while the UA package is a three-lead ultra-small SIP for through-hole mounting.

The package is halogen-free and has been verified by a third-party laboratory.

Product features

2. Power pin reverse bias protection

3. Chopper-stabilized amplifier

4. Optimized for BLDC motor applications, reliable and low shifting under high temperature conditions

5. Good ESD protection

6. 100% tested for K at 125℃, customizable sensitivity/temperature selection

Main applications

1. High temperature resistant fan motor

2. Three-phase BLDC motor application speed control

3. Position control

4. Current sensor

5. Speed measurement

6. Solid-state switch

7. Linear position detection

8. Angular position detection

9. Proximity detection

10. High anti-static ability

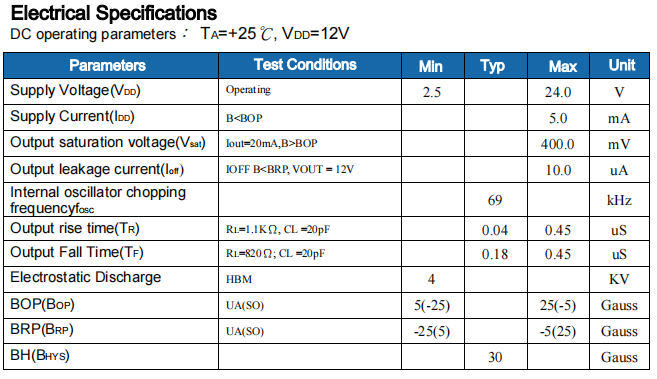

Product parameters

English

English Chinese

Chinese Dongguan Hallsen Technology Co., Ltd

Dongguan Hallsen Technology Co., Ltd